Type III prestressed reinforced concrete sleepers are designed for railways with a nominal track gauge of 1520 mm, which are used by typical rolling stock with axle loads and speeds established for the general network of railways of the Republic of Kazakhstan. Cross ties are produced in accordance with GOST 33320-2015 "Concrete Cross Ties for Railways. The type III concrete sleepers are screwed with any Fosslo type fasteners, including Skl Sl Super, Skl 14, Skl SL1, Skl 30 and others.

In addition to standard sleepers for P65 rails, BENT LLP. is the only plant in the country producing reinforced concrete sleepers for P50 rails. In addition, our plant is one of the two plants producing concrete sleepers of increased operational reliability "B50". Our company is also able to produce and deliver reinforced concrete sleepers for any rail gauge.

|

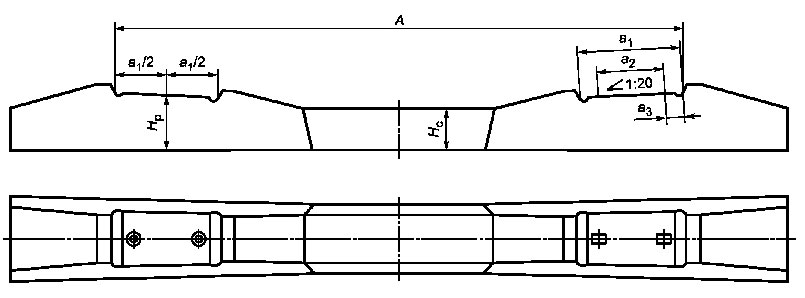

Technical characteristics of sleeper type III |

|

|---|---|

| 1. Frost resistance | F200 |

| 2. Concrete compression class | В40 (550 кгс/см2) |

| 3. Calculated operating load per axle | 25 tonnes |

| 4. track width | 1520 mm |

|

5. Overall dimensions:

|

|

| 6. Weight without stapling | 270 kg |

PRODUCTION TECHNOLOGY FOR CONCRETE SLEEPERS

The technology of manufacturing reinforced concrete sleepers used at BENT LLP is an aggregate-flow technology, i.e. metal moulds are moved from one technological station to another. Technological equipment and applied rigging are automated, mechanized as much as possible and represent a closed production cycle.

The production of concrete sleepers involves 2 spans of 144x18 metres with an annual production capacity of 800,000 concrete sleepers.

Materials used in the production of concrete sleepers

Reinforcement material - high-strength wire with a diameter of 3 mm, grade 3 Br1500-1;

Crushed stone - fraction 5-20 mm, strength not lower than 1200;

Sand - washed with a grain size modulus (Mkr.) 2,5 - 3,2;

Cement - Portland cement CEM 42,5;

Superplasticizing additive - ADM.

All materials have certificates of conformity of quality and constantly undergo incoming inspection of the certified laboratory of the plant of complex reinforced concrete structures of "Firma BENT" LLP.